Long Production Cycle

Optimize Production Cycles

Hight Speed Return∣Shorter Cycle Time∣Increased Production Capacity∣Reduced Operating Costs

Application: High-volume, high-capacity production lines

This solution leverages high-speed return and accurate positioning to dramatically shorten cycle times and maximize equipment utilization. The result: greater productivity and lower cost per unit.

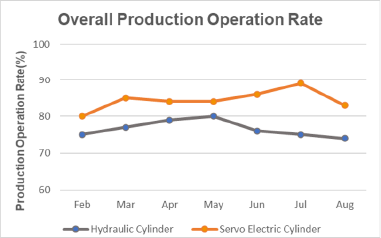

Company A

Overall Operating Rate Improved by Over 10%

Daily Production Comparison

Hydraulic Cylinder 2,198Modes/15. 2H

Servo Cylinder 2,445Modes/15. 3H

----------------------------------------------------------

Daily Output Increased by 247Modes

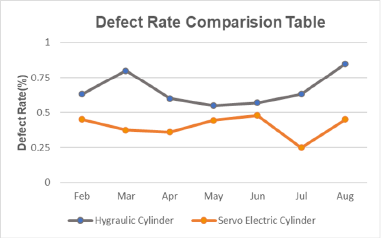

Significant Quality Improvement: Defect Rate Dropped from 0.7% to 0.4%

During the casting process, effectively reducing vibration enhances the stability of the sand core, preventing displacement or deformation during pouring and thereby minimizing the occurrence of casting defects such as porosity.

Company B

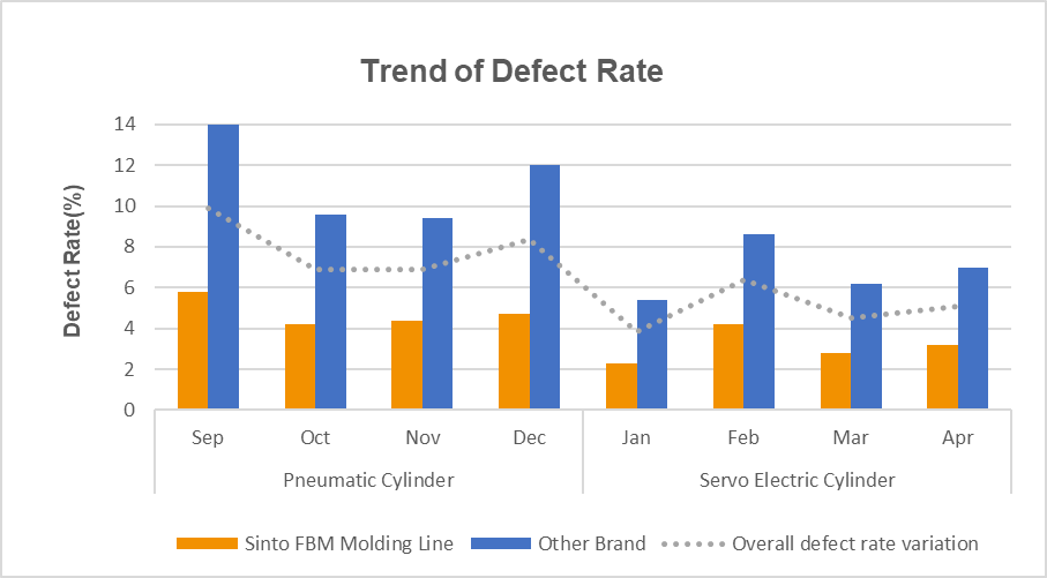

Quality Evolution through Servo Technology

During an eight-month observation period, the introduction of Sinto equipment initially reduced defect rates by approximately 50%. After further integrating servo electric cylinders into the molding line, product consistency and stability improved even more, achieving continuous reduction in defects and outstanding process optimization.

※ Based on customer survey data collected by our QA department.

Whether you need answers, solutions, or simply wish to share your ideas, we are pleased to assist you.

Contact email: sales@twsinto.com.tw (觀音廠)