STEEL SHOTS

Taiwan Sintong Machinery, the leading manufacturer, supplier and exporter of steel abrasive media,produces a wide range of metal abrasive products that surpasses the industry standards.

With over 40 years of experience in the industry, we stand as the primary steel abrasive product provider in Taiwan and throughout Asia.

We offer quality products and services to meet the specifications of our valued customers in a timely manner.

While we follow the strict manufacturing guidelines of ISO 9001, ISO 11124-3, and SAE J827, J444, our quality management systems have been assessed and registered as meeting of ISO 9001.

Steel shots are one of the steel abrasive media we specialize in manufacturing.

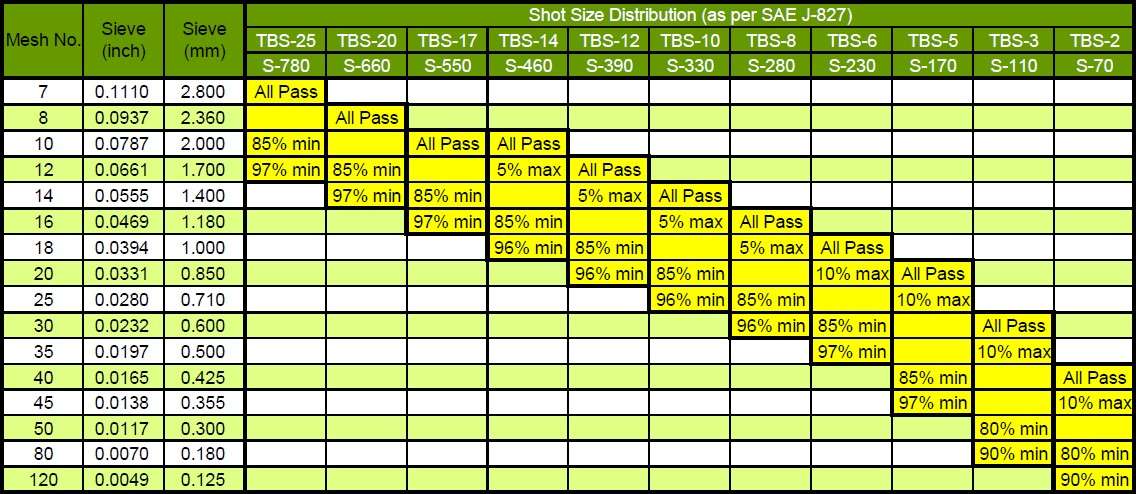

Product Specification

Product Applications

| TBS Standard | SAE Standard | Taiwan Sintong Machinery Steel Shots Application |

|---|---|---|

| TBS-25 | S-780 | Blast cleaning of large steel & iron casting. |

| TBS-20 | S-660 | Blast cleaning of large steel & iron casting. |

| TBS-17 | S-550 | Blast cleaning of large and medium steel & iron casting. |

| TBS-14 | S-460 | Blast cleaning of large and medium steel & iron casting. |

| TBS-12 | S-390 | Blast cleaning of medium and small steel & iron casting, descaling and peening of forgings and plates |

| TBS-10 | S-330 | Blast cleaning of medium and small steel & iron casting, descaling and peening of forgings and plates |

| TBS-08 | S-280 | Blast cleaning of small steel & precision casting, descaling and peening of medium thin sheets |

| TBS-06 | S-230 | Blast cleaning of stainless steel, thin sheets, non-ferrous castings. |

| TBS-05 | S-170 | Blast cleaning of stainless steel, thin sheets, non-ferrous castings. |

| TBS-03 | S-110 | Blast cleaning of stainless steel, thin sheets, non-ferrous castings. |

| TBS-02 | S-70 | Blast cleaning of stainless steel, thin sheets, non-ferrous castings. |

| Special Requirements are all available | ||

Salient Features of Taiwan Sintong Machinery Steel Shots

- Long lasting

- Versatile

- High abrasion resistance

- Cleans faster and consumes slower

- Uniform density

- Uniform hardness

- Dimensionally accurate

- Manufactured in accordance with the prevailing international quality standards

The exceptional properties, which renders them highly resistant and durable, of the steel abrasives we manufacture are a direct result of the advanced technology we use during the production process. Advanced technology we incorporate in the manufacturing process is transferred from Japan Sintokogio Ltd.

Application

Steel shots are used for a variety of purposes. Following are some of the utilities of steel shots.

- Shot Peening

Steel shots are used in shot peening, which is the process of enhancing the fatigue life of products (such as turbines, springs, gears, torsion bars, shafts, stabilizers, con-rods) that are affected by various stresses in use. - Surface Preparation

Steel shots can be used to prepare the surface by roughening it up to give a good key in support of coatings, such as powder coating, enamelling,, painting, metallisation, rubber bonding and more. - Sand Removal

Steel shots can be used in cleaning of castings. - Scale Removal

Steel shots can also be used to clean ferrous or non ferrous alloys or products (pipes, plates etc.) that are made from forging, die-forging, stamping, drawing and rolling or after heat treatment. - Shot blasting of cast steel

Steel shots can be used on the blasting of profile steel,ship board,steel board and other steel material - Roughening and de-burring

Steel shots are used in the aesthetic treatment of some material. It is also used to remove the burrs that might arise during injection moulding of metallic products.

Application Devices

Steel shots are mainly used with the devices mentioned below

- Shot peening machines and shot peening equipment

- Sandblasting machines and sandblasting equipment

- Rotary barrel shot blasting machines

- Pedrail type shot blasting machines

- Chain type shot blasting machines

- Pendent-chain and pile-type shot blasting machines

- Trolley type shot blasting machines

- Table type shot blasting machines

- Abrator equipment

- Steel material/ plate/ structure pre-treatment production line

Industries

- Automotive industry

- Construction industry

- Metallurgy field

- Petrochemical industry

Recyclability and Environmental Impact

Steel shots are highly recyclable; their recyclability ranges between 2000 and 3000 cycles. Thus, compared to other expendable abrasives, they generate less waste. Also compared to lead shots, steel shots are three times harder and lower in density.

Product Characteristic

Our Team

Our in-house team consists of dedicated and trained professionals who work continuously to manufacture high quality steel abrasive products that meet and surpass industry standards. Our qualified engineers, quality controllers and technicians work tirelessly to make sure that the end product is flawless. We are also able to customize the steel abrasive products by altering their strength, shape, density etc. to meet your specific requirements.